The difference between a winch and a hoist:

So many customers have asked this question, so we thought we would post it for your convenience.

What is the difference between and WINCH and a HOIST?

A Winch is for pulling, a Hoist is for Lifting.

You could probably push or move your car, but you could never dead lift it. A Hoist is geared differently and has locking brakes to hold a load.

A Winch is for pulling a load, most of the time has dynamic brakes, but can slide.

If a Hoist can lift 250 lbs, it can likely pull 1000 lbs.

If a winch can pull 1000 lbs in can probably only lift 100 lbs.

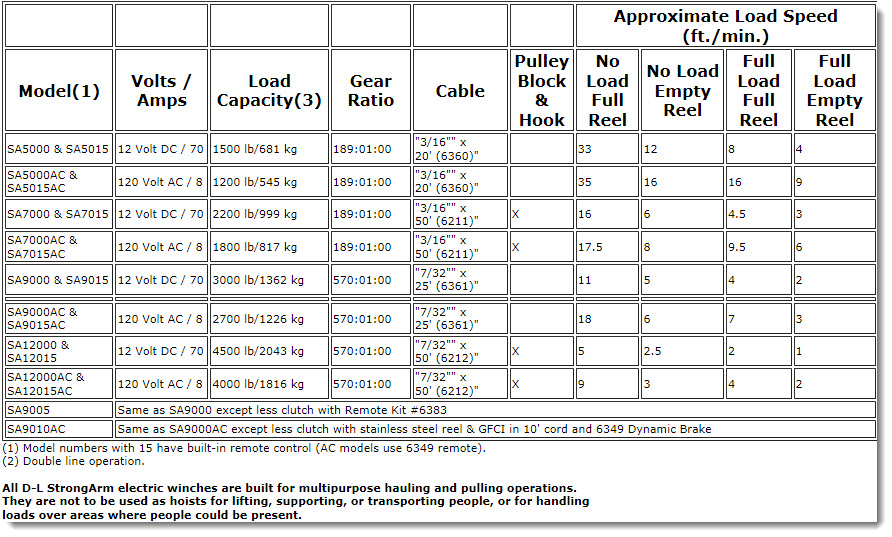

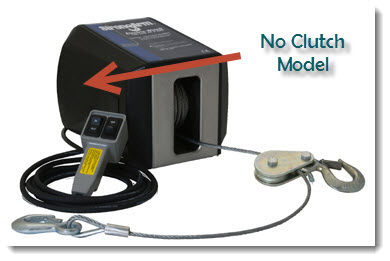

Some winches have a "Lifting" and a "Pulling" capacity ratings. These winch/hoist products are made to your specs when you order them and designed to do duel industrial jobs.

That is why on some of our other winches you see two different sets of specs. One for the lifting capacity, and another for the pulling capacity of the product.